- Author Bulk Hemp Warehouse

- Categories: Hemp Education, Hemp Farming, Hemp Fibers

Innovations in Hemp Fiber Processing for 2026

Hemp fiber processing has undergone significant advancements in recent years, paving the way for more efficient and sustainable practices and bringing it back home to the USA once again.

As industrial hemp production continues to grow, the demand for high-quality natural fibers has surged, especially in the textile industry and other industrial applications.

The development of innovative techniques and equipment has made the use of hemp a viable alternative to synthetic and other natural fibers, reducing the environmental impact of traditional manufacturing processes.

With the growing interest in hemp cultivation across North America and the global market, researchers and hemp growers are exploring improved production and processing practices.

From field retting to modern chemical processing, the hemp industry is experiencing a hemp fiber renaissance.

Some of the advancements not only enhance fiber yield and fiber quality but also expand hemp’s potential as a key raw material for diverse applications, from hemp clothing to construction materials, bioplastics and more.

Key Methods and Techniques in Hemp Fiber Processing

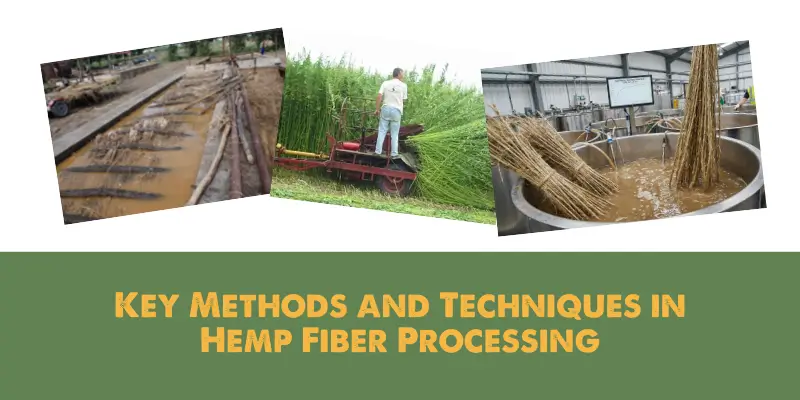

Traditional Processing: Dew and Water Retting

For centuries, traditional methods like dew retting and water retting have been vital for extracting fibers from hemp stalks.

Dew retting involves spreading hemp stems in a field and allowing the natural microbial processes to break down the pectin that binds the fibers to the inner woody core (hurd fiber).

However, this method depends heavily on weather conditions, such as adequate moisture and warmth, to ensure effective separation of the bast fiber from the inner core.

Water retting, on the other hand, involves submerging hemp stalks in water to achieve the same breakdown of pectin.

While this method often results in higher-quality fibers for textile applications, it has a notable environmental impact.

In fact, to my knowledge, China has recently banned water retting because of this, forcing hemp farmers to use more modern processes.

Which we will cover in just a moment.

The process can release significant amounts of organic matter into water sources, potentially affecting water quality.

As such, there has been increasing interest in modernizing these traditional methods to reduce their ecological footprint while maintaining fiber quality.

Modern Techniques: Chemical and Mechanical Processing

Modern advancements in chemical processing have revolutionized the production of industrial hemp fiber.

Chemical treatments help to expedite the separation of bast fibers from the woody core, resulting in higher fiber yield and improved fiber quality.

However, chemical processing often raises concerns about energy consumption and its environmental impact, prompting efforts to develop more sustainable extraction methods.

Mechanical processing techniques, such as the use of hammer mills and wet spinning, have also gained traction in recent years.

Hammer mills are effective in breaking down hemp stalks into finer components, including bast fiber and hemp biomass material.

Wet spinning, a technique borrowed from the textile industry, enhances the production of uniform fiber bundles suitable for quality textiles.

These innovations not only improve efficiency but also broaden the use of hemp in both traditional and industrial applications.

One known chemical process is enzyme retting, which is a relatively natural process that helps digest lignans and pectins.

What enzyme retting is

Instead of relying on naturally occurring microbes, enzyme retting uses specific enzymes that target the exact components you want to break down — mainly pectins and some hemicelluloses.

These enzymes are added in controlled conditions (usually warm water tanks), giving you consistent, high-quality fiber without the smell, pollution, or unpredictability of traditional retting.

The main enzymes used in enzyme retting

1. Pectinases

The star of the show.

These enzymes cut through pectins, the binding agents between fiber and hurd.

2. Hemicellulases (xylanases)

Help break down hemicellulose to further loosen bundles and improve fiber fineness.

3. Laccases / peroxidases (optional)

Used to partially modify lignin, improving color and softness.

Why do companies use enzyme retting?

- Faster (hours to 1–2 days, instead of weeks)

- Cleaner fiber (more uniform, brighter, stronger)

- Less odor than traditional retting

- Environmentally friendly (no anaerobic runoff)

- Predictable results (controlled pH, temp, and enzyme concentration)

- Ideal for textile-grade fiber

What enzyme retting DOES NOT DO

It doesn’t dissolve:

- Cellulose

- The structural integrity of the bast fibers

It only removes the materials that hold the fibers in place.

Bonus: Two enzyme retting approaches

Closed-tank enzyme retting

Industrial, controlled, fast.

Spray-on enzyme field retting

A hybrid method: enzymes are sprayed on windrows to speed up or standardize dew retting.

What’s actually being broken down during retting?

1. Pectins — the main target

These are the natural binders that cement the bast fibers to the hurd (woody core).

Retting essentially dissolves or decomposes these pectins so the fibers can be separated cleanly.

2. Hemicellulose

This softens during retting and helps loosen the fiber bundles, making the fibers more flexible and easier to extract.

3. Lignin (to a lesser extent)

Lignin is tougher and doesn’t fully break down during retting, but it does partially degrade or loosen, helping the fibers separate.

4. Waxes and surface materials

Microbial activity reduces some of the waxy coatings, helping water penetrate and release the fibers.

Stages of Hemp Fiber Processing and Its Applications

Breaking Down Hemp Stalks and Stems

The first stage of processing involves breaking down hemp stalks to separate their primary components: the bast fiber, and hurd fiber.

Each part of the plant serves distinct purposes, making this stage crucial for optimizing the entire production system.

The bast fiber, which consists of long fibers, is ideal for textile and woven applications, among other things, while the woody core is often used in construction materials (hempcrete) and animal bedding.

Moisture content plays a significant role in ensuring that the separated fiber bundles maintain their integrity and are suitable for end use.

Proper drying and storage techniques are essential to prevent the degradation of natural fibers, which can compromise their usability in applications like hemp fabric or building materials.

Effective separation and processing of these components ensures minimal waste and contributes to the overall efficiency of hemp fiber production.

Diverse Applications of Hemp Fiber

Hemp fiber has a wide range of applications, making it one of the most versatile natural fibers available on the market.

In the textile industry, hemp textiles/hemp fabric are becoming increasingly popular due to their durability, breathability, and eco-friendly nature.

Hemp clothing, for instance, is celebrated for its ability to replace synthetic fibers while maintaining a lower environmental impact.

It doesn’t require herbicides, pesticides, fungicides, larvicides, and doesn’t need to be genetically modified with toxic Roundup-type technology.

Beyond textiles, hemp fiber is widely used in construction materials, including hempcrete, which offers a sustainable alternative to traditional building materials, particularly as a fire-resistant, pest-resistant, mold-resistant, and very healthy insulative type material.

The woody core and bast fiber are also utilized in industrial products, including composites and garden mulch, as well as in animal bedding due to its high absorbency and renewability.

These diverse applications highlight the benefits of hemp as a renewable resource with significant potential to reduce reliance on fossil fuels and non-renewable materials.

Hemp Fiber Processing in the United States and Globally

The Hemp Industry in North America

The legalization of industrial hemp under the Farm Bill has significantly boosted hemp farming and seed production in the United States.

This legislative change has allowed more farmers to participate in hemp cultivation, contributing to the growth of the hemp market in North America.

Organizations like the University of Kentucky have played a pivotal role in advancing hemp research and production practices, offering valuable insights into fertilizer recommendations, growing conditions, and harvesting techniques.

Hemp programs across the United States aim to support hemp growers by providing resources and establishing networks within the value chain.

These programs not only facilitate the processing of hemp for various end uses but also ensure that production systems are optimized for maximum fiber yield and quality.

As the demand for hemp textiles, construction materials, and other industrial products grows, the United States is poised to become a key player in the global hemp industry.

Global Trends in Hemp Fiber Production

Globally, hemp cultivation is gaining momentum, particularly in regions like the European Union, where favorable policies and production systems support the growth of the hemp industry.

European hemp growers focus on producing higher-quality fibers for textile applications while also contributing to grain production for hemp seed oil and animal feed.

The diverse varieties of hemp cultivated in Europe are tailored to meet specific end uses, ensuring a steady supply of raw materials for both traditional and industrial applications.

Comparing growing conditions between North America and Europe reveals differences in production practices and fiber quality.

While North America is still expanding its industrial hemp production infrastructure, European countries have a more established value chain for hemp textiles and industrial hemp fiber.

These global trends indicate that the hemp industry is on the cusp of significant growth, driven by increasing awareness of hemp’s environmental benefits and its potential to replace synthetic fibers in various sectors.

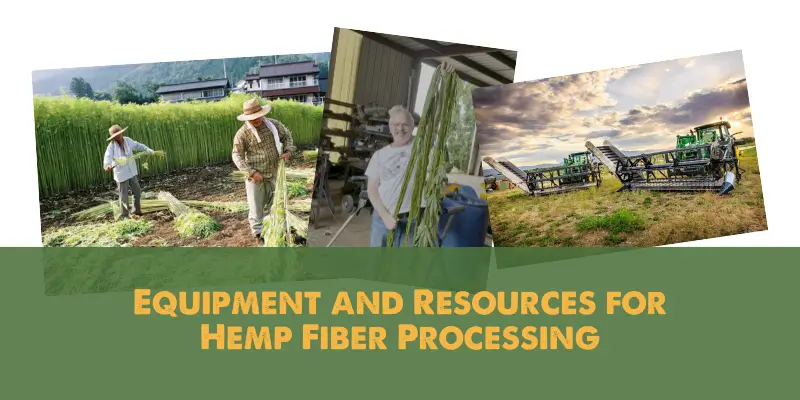

Equipment and Resources for Hemp Fiber Processing

Investing in Machinery and Production Practices

Modern hemp fiber processing requires efficient machinery and innovative production practices to meet the growing demand for industrial applications.

Hammer mills are essential tools for breaking down hemp stalks into manageable components, including bast fiber and the woody core.

These machines ensure precision and speed, reducing labor costs and improving overall efficiency.

Additionally, chemical processing tools and advanced extraction methods are being developed to optimize the separation of cellulose fibers for higher-quality fibers used in textile and industrial sectors.

Energy consumption is a critical consideration when investing in machinery. Innovative equipment is now being designed to reduce energy use while maintaining or enhancing fiber quality.

By adopting sustainable processing techniques, hemp farmers and manufacturers can minimize their environmental impact while maximizing profitability.

These advancements highlight the importance of balancing production efficiency with eco-friendly practices in the evolving hemp industry.

For a deep dive into the hemp fiber harvesting and processing for hemp textiles, check out this infographic and article we put together on that.

Connecting to Processors and Support Networks

For hemp growers, building connections within the value chain is vital to ensure smooth processing and distribution.

Organizations like Bulk Hemp Warehouse provide essential support by linking farmers with processors and buyers, creating a streamlined system for hemp fiber production.

These networks play a crucial role in helping hemp farmers access resources and opportunities in the textile and industrial sectors.

Collaborations with industry players and research institutions, such as the University of Kentucky, further strengthen these networks.

By sharing knowledge on fertilizer recommendations, growing conditions, and processing techniques, these partnerships foster innovation and sustainability.

This collaborative approach ensures that hemp farming and processing continue to evolve, meeting the needs of both local and global markets.

The Future of Hemp Fiber Processing and Its Benefits

The future of hemp fiber processing lies in its potential to replace synthetic fibers with eco-friendly natural alternatives.

By reducing reliance on fossil fuels, hemp can contribute to improved air quality and a more sustainable economy.

Innovations in hemp textiles and other industrial applications are paving the way for a greener future, where environmental impact is minimized without compromising functionality.

Hemp’s versatility extends to industrial products, hemp seed oil, and construction materials, making it a key component in reducing the carbon footprint of various industries.

As hemp research and production systems continue to advance, the benefits of hemp will become increasingly evident, solidifying its role in shaping a sustainable and economically viable future.

Interested in becoming a hemp fiber processor?

If you’re a farmer or want to become a hemp fiber farmer and are looking for a cutting-edge piece of hemp fiber processing technology, reach out to us today and ask about a brand new hemp fiber decorticator that we are helping bring to the market. To learn more, call today: 805-410-4367

OTHER EDUCATIONAL HEMP POSTS

Explore Other Posts by Bulk Hemp Warehouse

Hemp Horse Bedding Instructions: Setup, Maintenance, and Change-Out

If you have ever walked into a stall first thing in the morning and caught that sharp ammonia smell, you already know why bedding choice matters. When working with Hemp for Horse Bedding Instructions, you are aiming for a cleaner,

Natural Hemp Rope: How to Spot Genuine Fiber and Choose the Right Type

Search data and marketplace audits keep pointing to the same trend: a surprising share of “hemp” listings online are not hemp at all, but other natural fiber rope substitutes with vague labeling. When shopping for Natural Hemp Rope, the difference

Why Hemp Seeds Are the Ultimate Superfood for Birds – And Why Corn, Wheat, and Soy Don’t Belong in Their Diet

Could hemp seeds be the NEW Bird Feed that beats corn wheat and soy? I think so.